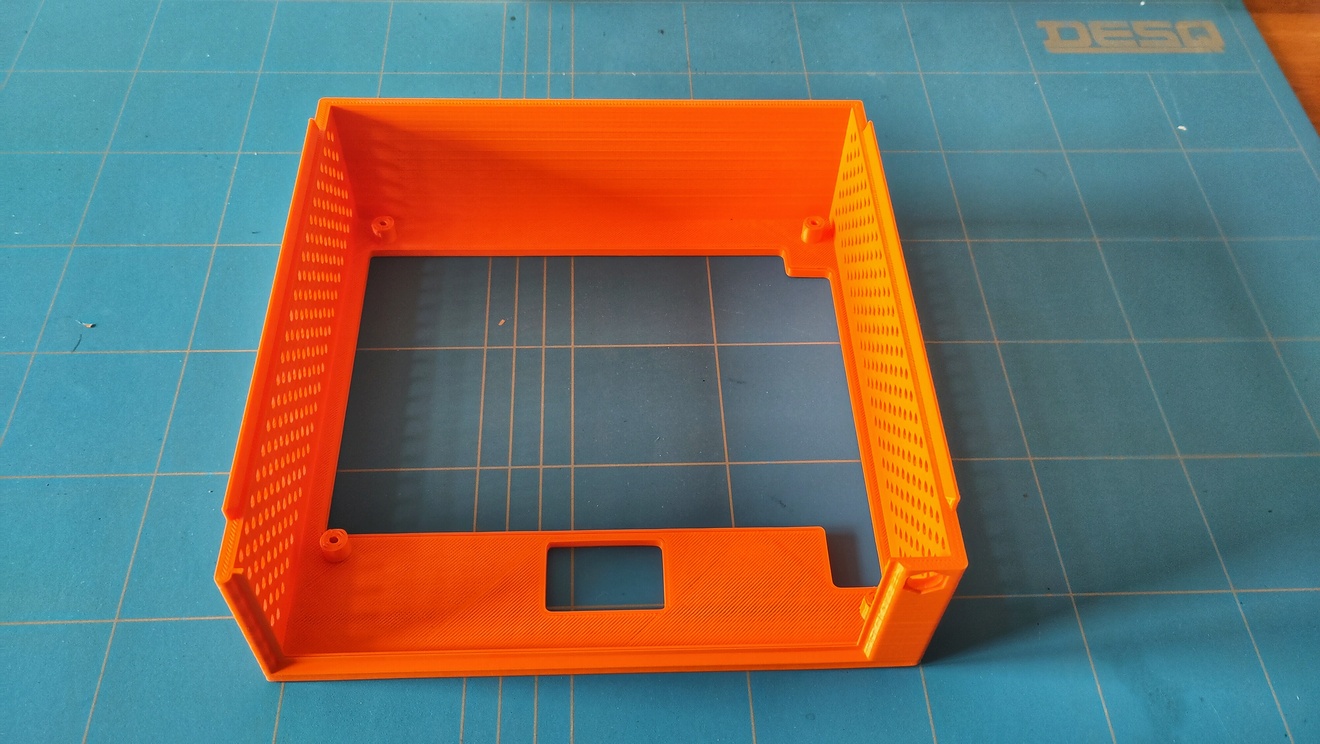

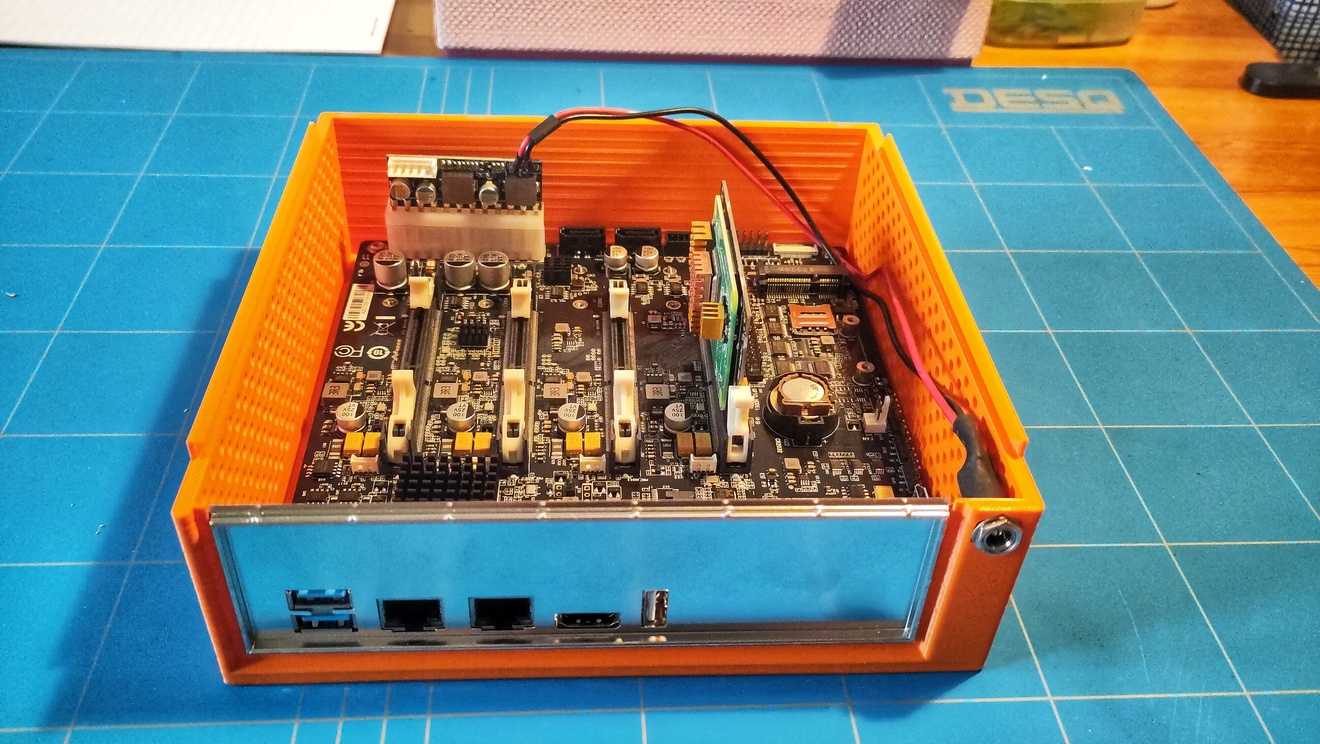

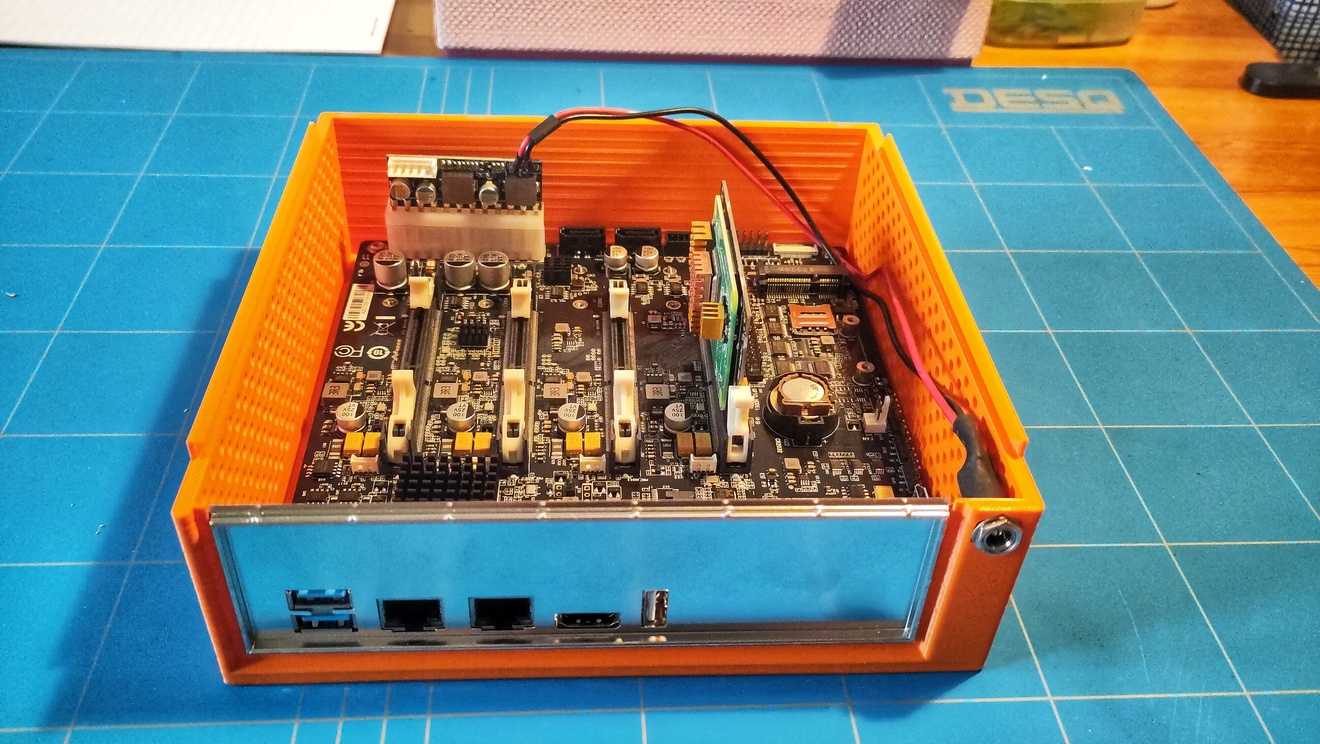

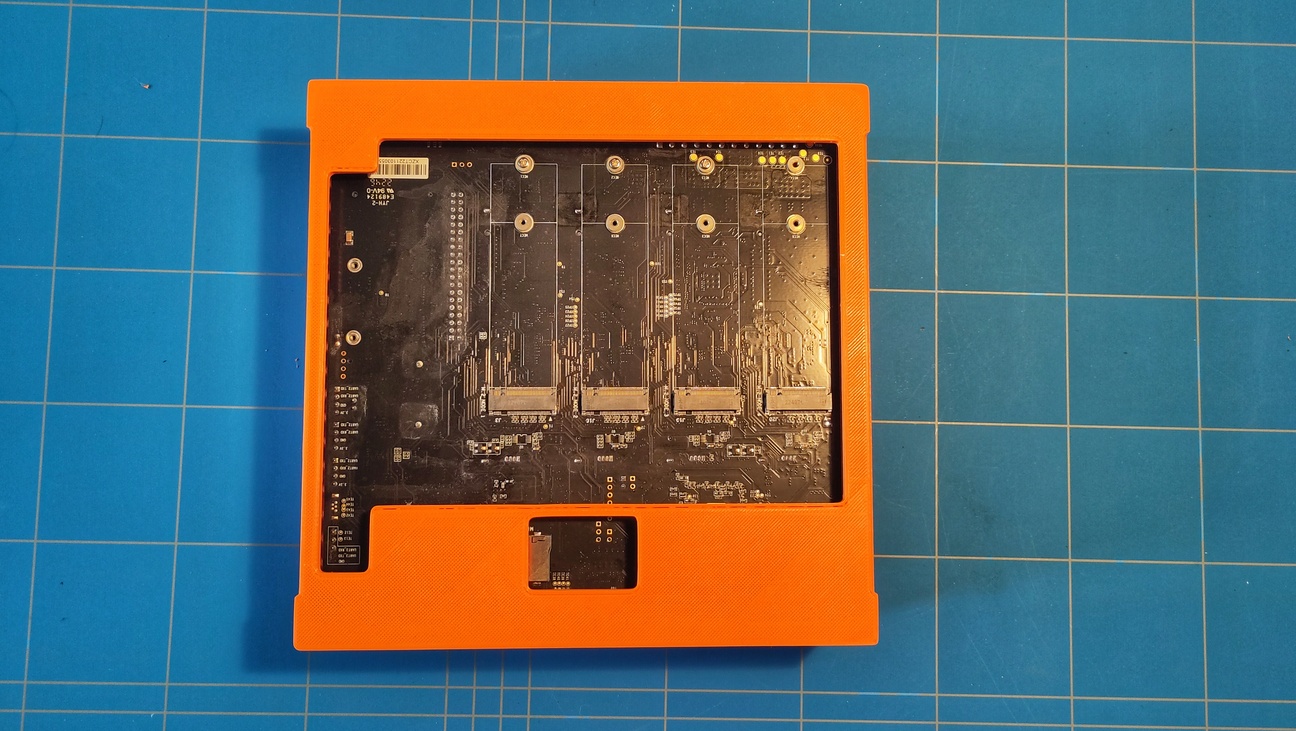

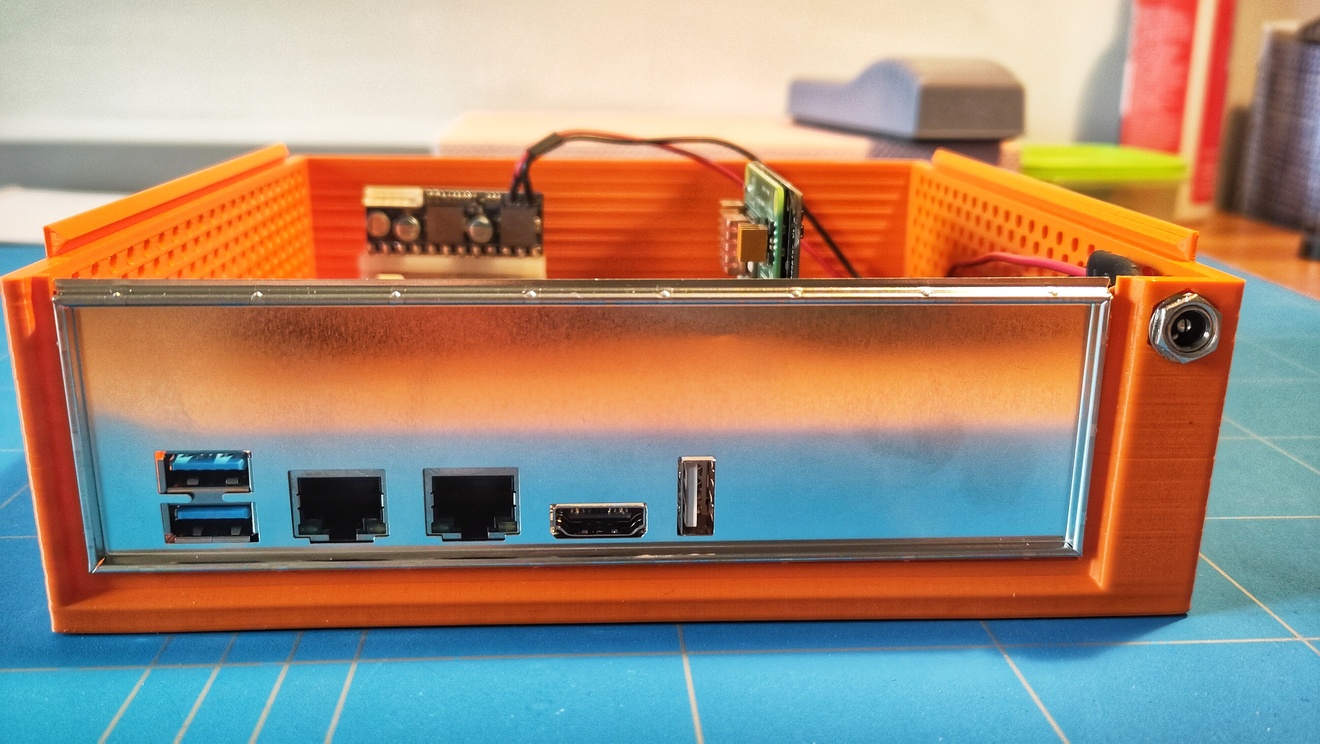

This week I 3d-printed a case for my Turing Pi v2. The excellent model I fabricated came from Sam E. (CFSworks) on Thingiverse (cc-nc, copy here), made with a lot of love. The model would be stackable, but I don’t need that. My Turing Pi as of now doesn’t have a top cover but that’s ok because it’s below a desk and the CM4 would be anyways sticking out.

The finished case looks brilliant.

If you wonder what the little hole in the first picture is, this is for the SD-Card on the bottom of the board for the BMC itself. It can be used as additional storage space therein, to e.g. hold installation medium or whatever.

The print turned out to be challenging. I had 3 failed prints, where the filament was stuck. For some reason the filament got crimped in such a way, that it didn’t fit through the second hole of the 3d-printer anymore. This happened 3 times roughly at the same time of print (after some hours). My hypothesis is, that the support material at this part needs to push the filament a lot back and forth because it always prints just a tiny little bit, and in the process at some point the filament gets squashed too much because the same place gets pushed back and forward over and over and over and over and over again.

I resolved the issue by disabling support material. There is only a little overhang, and the printer should be (and was) able to print this without support. It also reduced the printing time by 1-2h.

The print itself took more than 24h on my Creality Ender 3. I used pretty much the default settings and PLA, which turns out to be just perfect. It feels sturdy, the TuringPi and the IO shield fit perfectly, and in general it has a good look and a good feeling. I’m happy with it 😀

So, here’s the result:

Big thanks to CFSworks for this amazing model. I keep a copy of it here on the Blog because it should be preserved.

This is the power of open source manufacturing. It took me some time to get it done, I’ve learned some new things and in the end I’m holding something amazing in my hand. How is this not awesome? 😀